AeROS® (Asset Reliability and Operations Simulation)

Request for DemoSystem requirements: Windows 10 or higher on PC.

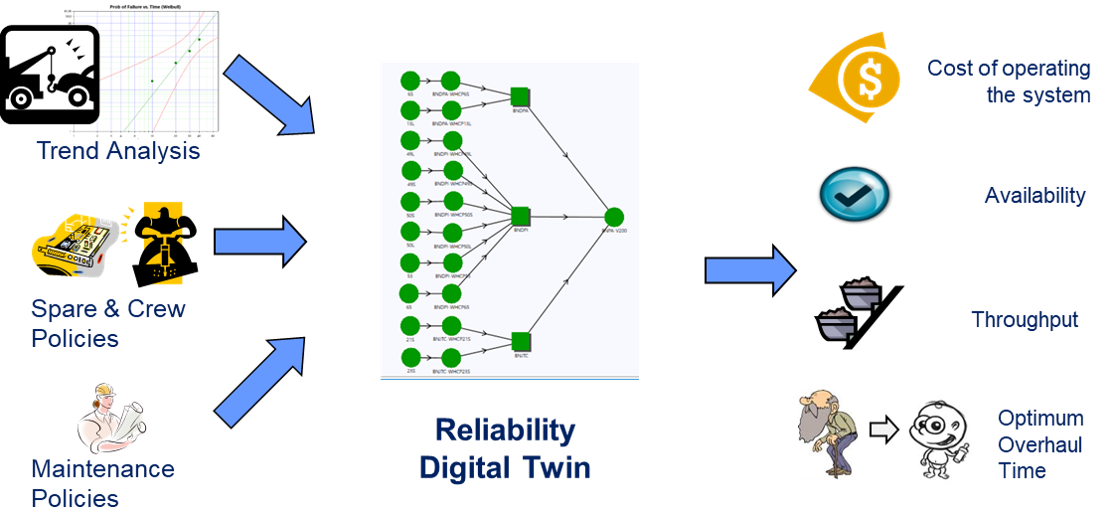

How AeROS® Works

AeROS® enables users to create a digital twin of production systems for predictive analysis using statistical approaches.

This digital twin forecasts potential future outcomes with a focus on production uncertainties. It delivers key insights into how asset performance and maintenance policies impact production—critical KPIs that reflect the financial health of your production assets.

Operating in a virtual environment, the digital twin facilitates simulations to optimize production performance. The results provide a foundation for cost-benefit analysis, supporting data-driven investment decisions.

How AeROS® Benefits You

- Analyze production impact of asset reliability and maintenance policies

- Assess production impact from supply and demand variations

- Identify performance gaps for targeted improvements

- Justify and track improvement programs with statistical evidence

- Optimize maintenance resource allocation

- Streamline spare inventory management

- Support comprehensive life cycle cost analysis

- Perform detailed cost-benefit analysis

- Conduct queueing theory analysis

- Execute proof-of-concept analysis

What Makes AeROS® the Premier Reliability Simulation Software

AeROS® extends beyond standard Reliability Block Diagram functionality (Series/Parallel, Sub-diagram, K-out-of-N) with advanced logical constructs and specialized features for realistic simulations:

- Supports both Repairable (equipment-level) and Non-repairable (component-level) life models

- Features Life-Stress Models using cumulative damage theory to analyze production rate impacts

- Includes Redundant Resource Manager for complex standby scenarios

- Provides Storage construct for buffering with configurable events (Full, Empty, High, Low thresholds)

- Features a Tristate plot to visualize operating profiles, displaying an item's operational states (running, standby, or down) alongside its production rate profile

- Delivers specialized plots: System Availability, System Flowrate, and Spare Availability

- Includes Reliability Improvement Allocation tool

- Features Spare Restock Optimizations batch calculator

- Supports Time-To-First-Failure analysis

- Incorporates Crews and Spares constraints for realistic scenarios

- Models flow rate variations with Flowrate Profile construct

- Enables User-defined CDF for random event modeling

- Provides a Startup construct to simulate equipment restart delays due to hidden failure mode

Reliability, Availability, Maintainability (RAM) and Simulation Case Studies

- Availability as a Reliability Metric in RAM Studies

- Quantifying Equipment Contributions to Production Loss Within a Production Network

- RAM Analysis of an Offshore Platform

- Inventory Management - Spare Restock Triggering Policy

- Estimating Field Return Distribution Based on Reliability Test Results and Surveyed Usage Profiles

- Production Impact of Supply Quantity Variations: A Queueing Theory Approach Using AeROS

- Optimizing Buffer Tank Size in Chemical Processes Under Equipment Reliability Constraints

- Modeling and Simulating a Renewable Energy System for Performance Analysis

- A RAM analysis for Consecutive-K-out-of-N data communication system

- RAM Modeling containing Items with Hidden Failure Mode

Testimonials

Customer-centric engagement is the foundation of our success. We strive for excellence, as reflected in feedback from our satisfied clients.

Principle Engineer

Petronas Carigali Sdn Bhd

"AeROS is remarkably user-friendly with features that significantly enhance workflow efficiency. The cost of ownership is substantially lower than comparable RAM software solutions in the market."

Project Manager

Leading Refinery Plant in Indonesia

"The advanced features in AeROS enable realistic production process modeling unmatched by other reliability simulation tools. This capability provides exceptional confidence in production system risk assessments."